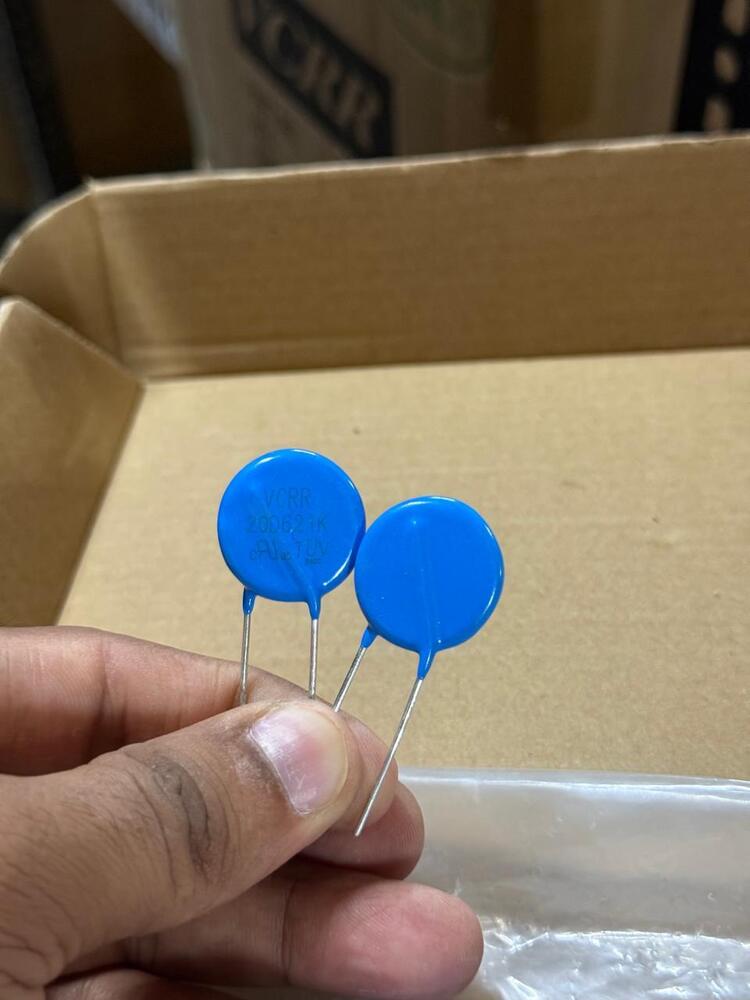

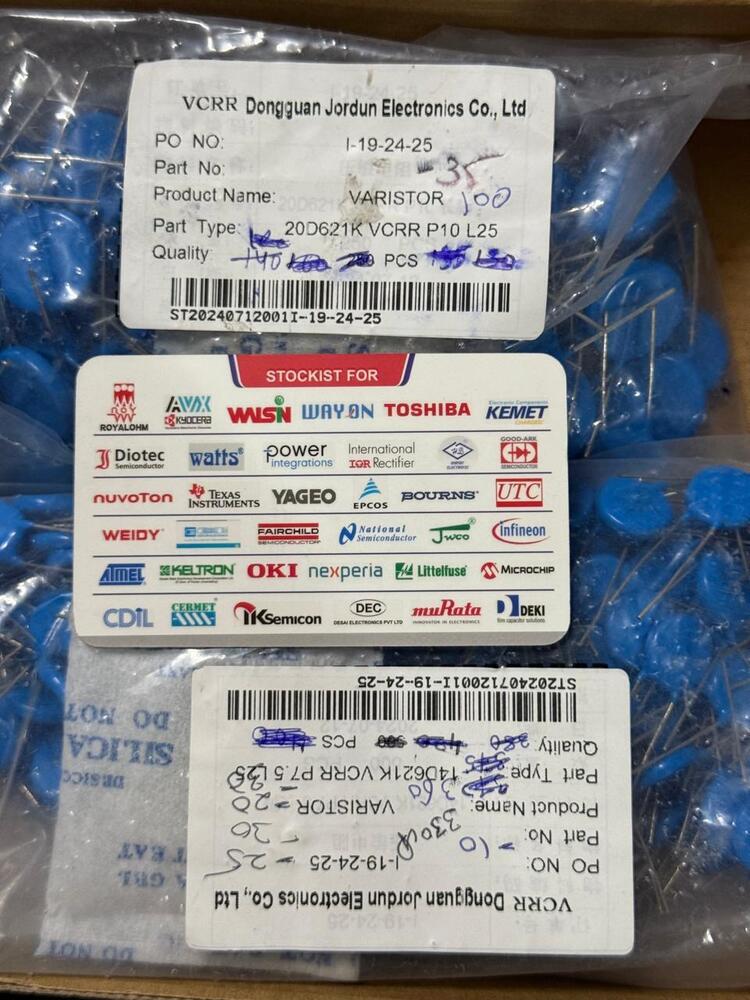

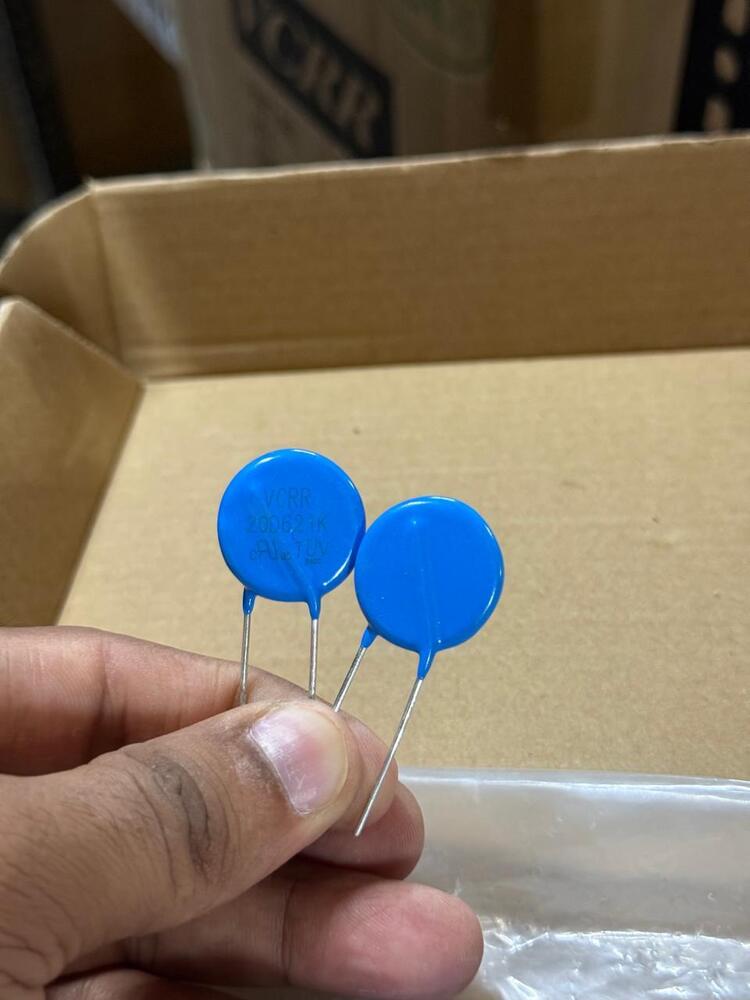

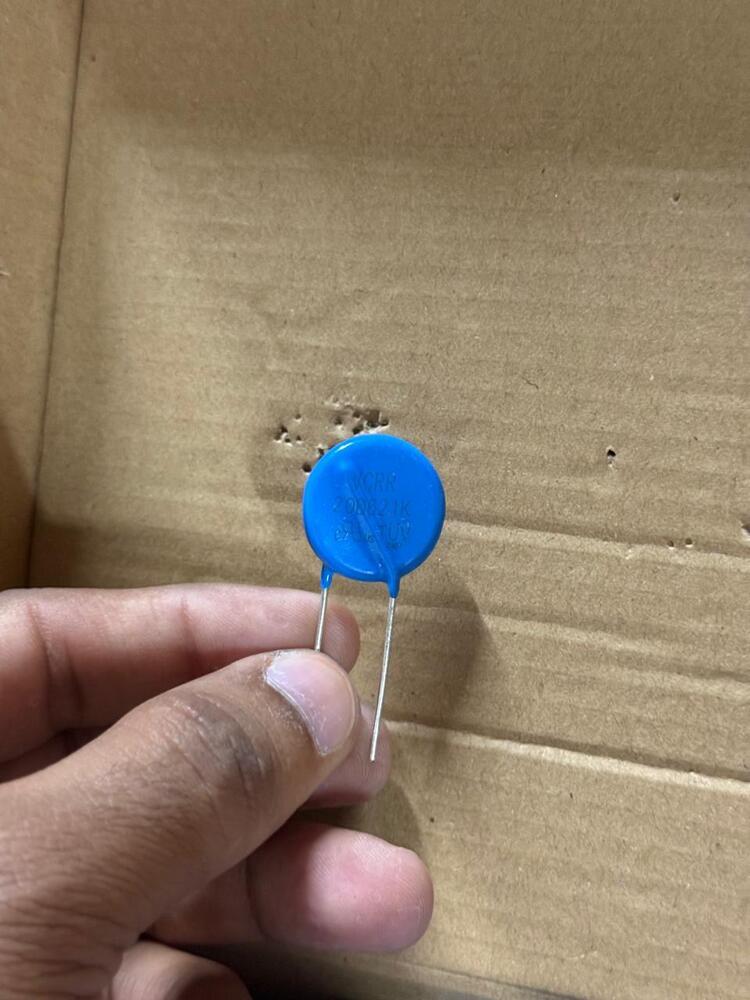

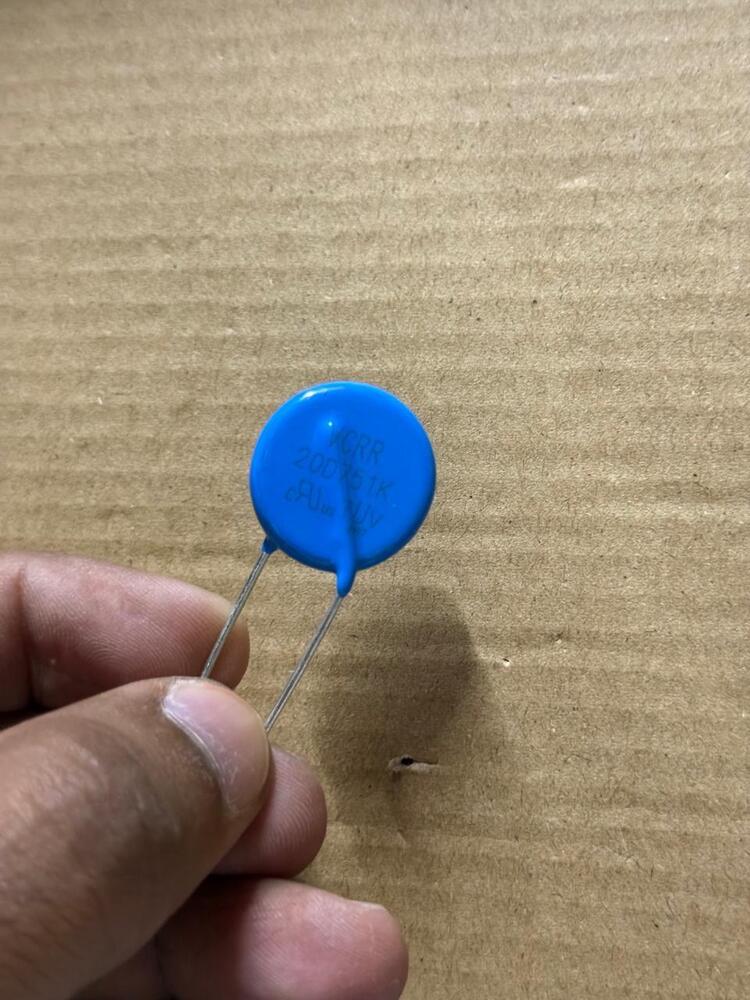

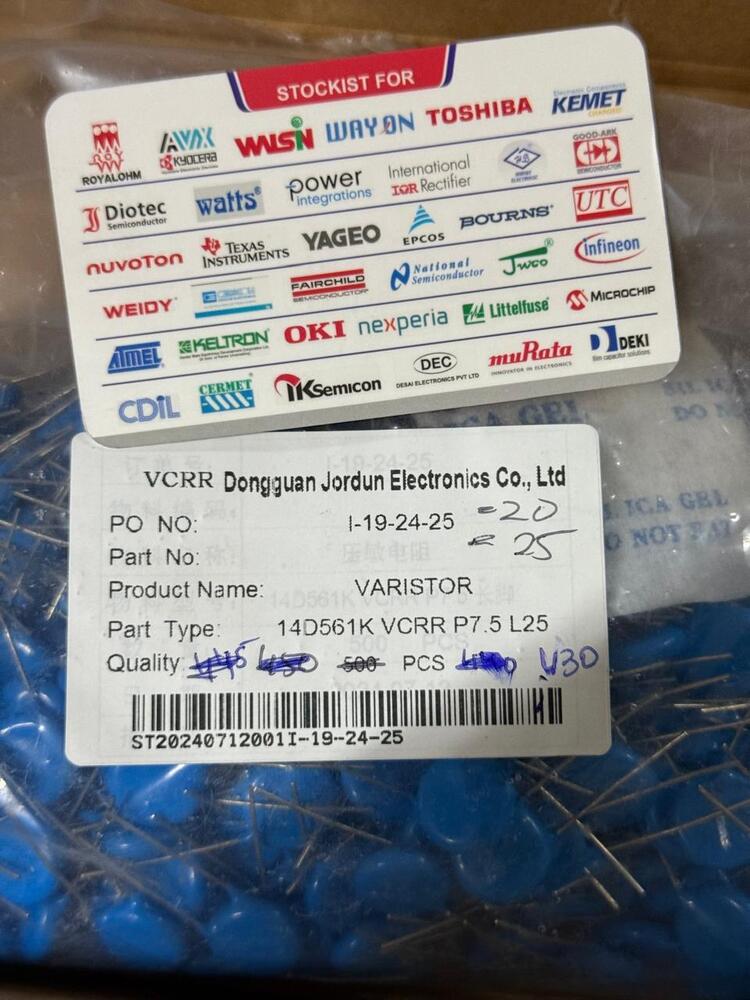

MOV-20D621K Metal Oxide Varistor Thakor (VCRR)

Product Details:

MOV-20D621K Metal Oxide Varistor Thakor (VCRR) Price And Quantity

- 500 Piece

- 4.00 - 12.00 INR/Piece

- 5 INR/Piece

MOV-20D621K Metal Oxide Varistor Thakor (VCRR) Trade Information

- Cash in Advance (CID)

- Asia

- All India

Product Description

MOV-20D621KMetal Oxide Varistor by Thakor (VCRR)

ProductDescription

The MOV-20D621K is a Metal Oxide Varistor(MOV) designed to protect electronic circuits and electrical systems fromvoltage surges and transient events. This varistor provides effectiveovervoltage suppression by clamping excess voltage levels and absorbinghigh-energy pulses. It is suitable for both AC and DC circuits, making it aversatile component for industrial, commercial, and residential applications.

TechnicalDetails

- Model: 20D621K

- Varistor Voltage (V): 620V

- Maximum Continuous Voltage:

- AC: 385V

- DC: 505V

- Clamping Voltage: 1,025V (at a current of 50A)

- Energy Absorption Capability: 220J

- Maximum Surge Current: 6,500A (8/20 µs waveform)

- Operating Temperature Range: -40C to +85C

- Disc Diameter: 20mm (standard for the "20D" series).

- Leads: Radial leads, tin-plated for secure soldering and corrosion resistance.

- Compliance: RoHS and UL recognized for safety and environmental standards.

Key Uses

- Surge Protection in Electronics:

Used in power supplies, adapters, and PCB designs to protect circuits from transient surges caused by lightning strikes, switching events, or power disturbances. - AC Line Protection:

Often installed in home appliances (air conditioners, refrigerators, and washing machines) and industrial equipment to protect against voltage spikes. - Telecommunications Equipment:

Protects telephone lines, modems, and signal transmission circuits. - Automotive Electronics:

Safeguards sensitive circuits in automotive applications such as ECUs, infotainment systems, and battery management systems. - General Overvoltage Protection:

Used in relays, sensors, and measuring instruments to ensure durability and reliability.

Benefits

- High Surge Current Capability:

Protects devices from high-energy transients, ensuring reliable operation. - Fast Response Time:

MOVs respond within nanoseconds, clamping voltage spikes before they can damage sensitive components. - Cost-Effective Solution:

Economical protection compared to other overvoltage solutions like TVS diodes or gas discharge tubes. - Versatile Applications:

Works effectively in AC and DC circuits, enhancing its usability across industries. - Compact Design:

The radial-lead package enables easy integration into space-constrained PCB layouts.

ComparableBrands and Part Numbers

If the MOV-20D621K by Thakor (VCRR) isunavailable, the following equivalent parts from other brands can beconsidered:

- Littelfuse

- Part Number: V20E385

- Specifications: Similar energy absorption and voltage ratings; widely used for surge suppression.

- TDK

- Part Number: B72220S0381K101

- Specifications: Offers excellent clamping characteristics and surge handling.

- EPCOS (TDK Group)

- Part Number: S20K385

- Specifications: Similar diameter (20mm) with nearly identical voltage and energy ratings.

- Panasonic

- Part Number: ERZ-V20D621

- Specifications: Comparable varistor voltage and surge current ratings.

- General Electric (GE)

- Part Number: V385LA20A

- Specifications: Meets industrial and consumer surge protection requirements.

ConsiderationsWhen Selecting a Replacement

- Match the varistor voltage (V) to your application to ensure proper operation.

- Ensure the replacement has a clamping voltage and energy absorption capacity equal to or higher than the original.

- Verify compatibility with operating temperatures and environmental conditions.

- Confirm compliance with applicable certifications (e.g., UL, RoHS).

If additional technical details or designrecommendations are needed, feel free to ask!

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free